PTFE powder, also micronized PTFE is a refined low molecular weight PTFE, which is almost entirely consumed in the non-fluoropoly- mer industry. Micropowder is added to other products to improve their performance and impart some fluoropoly- mer properties to the substrate. Its relative density is 2.2g/cm3, with a dosage of 4% to 30% according to the customer’s product.

The application field of Tianshi PTFE Powder:

1. Engineering plastic modification

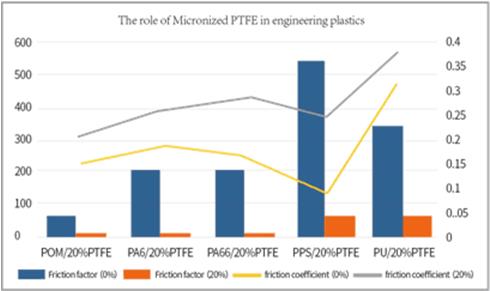

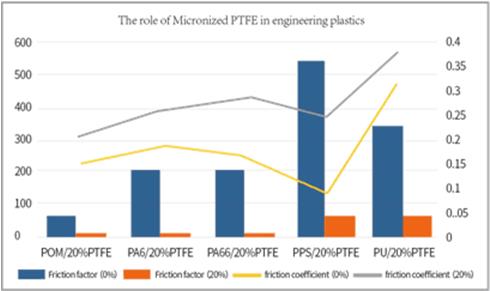

The Tianshi Micronized PTFE product is applied to the ienieeareabes Miaeee nace modification of engineering plastics, which can significantly improve the wear resistance and lubricity of engineering, such as nylon (PA), polyphenylene sulfide (PPS), polycarbonate (PC), polyformaldehyde (POM), polyimide (PI), polyester (PET), polysulfone (PSF) and other resins. The addition of Micronized PTFE improves the tribological properties of the polymer. These improvements are helpful for engineering plastics to replace lubricated metal parts, thus providing wear and corrosion resistance.

2. Rubber elastomer

2. Rubber elastomer

The Tianshi Micronized PTFE product is used in rubber elastomers to significantly enhance the surface and overall performance of the part. Surface properties include demolding, friction, wear and lubricity; overall properties include tear strength, abrasion resistance and flexural life. The fluorine additive can be mixed into the elastomer by a conven- tional method, and the high concentration (up to 30-50% of the mass of the elastomer) of the Micronized PTFE will not hurt the elastic behavior of the elastomer.

3. Lubricating oil and grease

3. Lubricating oil and grease

The Tianshi Micronized PTFE product can be used in lubricating oil and grease not only to enhance lubricity but also for cooling, energy transfer and insulation of electrical equipment. The product can also be added to high performance greases as a stable thickening agent to improve its durability and reliability in harsh environments. When added to grease, the product is able to reduce wear and friction coefficient, sliding adhesion and system torque. Examples of applications include camera parts, aerospace parts, plastic gears, valves and ski equipment.

4. Dry lubricant

The Tianshi Micronized PTFE can be directly applied as dry powder, such as automobile wax, chain oil, brake pad, etc., or sprayed directly on the surfaces such as sliding blocks, cables, glass cloth, sliding windows and locks. The product has a lower friction coefficient and higher cleanliness than graphite and molybdenum disulfide.

Technical Parameters:

| Dry friction agent |

Static friction coefficient |

| Micronized PTFE |

0.06-0.07 |

| Molybdenum disulfide |

0.15 |

| Graphite |

0.15-0.16 |

5. Anti-Dripping agent

Features and uses:

a. the anti-dripping agent PTFE-200D is pure PTFE, which is mainly used in the flame retardant of engineering plastics to prevent dripping.

b. can be added to PC,ABS,PC/ABS.PBT,HIPS

c. strong fibrotic ability

d. excellent liquidity and dispersion

e. excellent appearance of molded products

f. low addition ratio(0.1-0.3%)

| Appearance |

White powder |

| Particle size (mesh) |

20 |

| Content (%) |

99 |

| Melting point |

325 |

TIANSWAX Successfully Completes Phase II of Nanjing Wax Powder Plant

TIANSWAX Successfully Completes Phase II of Nanjing Wax Powder Plant

Driving the Green Coatings Revolution with High-Performance Wax Innovation: Nanjing Tianshi's Technological Breakthrough and Industry Responsibility P

Driving the Green Coatings Revolution with High-Performance Wax Innovation: Nanjing Tianshi's Technological Breakthrough and Industry Responsibility P

JLU Celebrates 70 Years of Materials Science: Tianshi Group President Delivers Keynote on “Precision Waxing, Changing the World”

JLU Celebrates 70 Years of Materials Science: Tianshi Group President Delivers Keynote on “Precision Waxing, Changing the World”