Comparing with traditional solvent-based coating, the powder coating don’t have volatile toxic substance to pollute the environment, but small molecular substances will be released during the reaction of solidification process, these small molecular substances combine to produce smoke, which is called as the smoking phenomenon.

The commonly used hardening agent and scratch resistant agent in the powder coating is polyethylene wax, its appearance is small white bead or flake and it has the characteristics of high melting point, high hardness, high gloss and white color, it melts at high temperature and precipitates when cooled to room temperature, it exists in coating in the form of microcrystalline and can migrate to the coating surface, it finally forms a waxed surface with other components of coating to achieve the effect of scratch resistant.

The wax powder has characteristic of easily melting at high temperature that makes a part of small molecular substances will inevitably precipitate from the surface to contact with air and resulting in the smoking phenomenon. The smoking phenomenon can cause visible smoke when the oven is opened during coating, and the coating enterprise will be considered to have environmental problems; or it will produce sediments in vertical baking oven which is easy to cause fire accidents.

In order to determine the volatility of different waxes, the following methods can be used:

1. Oven weight-loss method: Take sample of 3g to place in an aluminum weighing dish with a diameter of 50mm, bake it in the oven of 220

℃ for 20min, then cool to room temperature to measure the weight loss rate.

2. TGA method: Take sample of 5mg to place in the TGA, increase the temperature to 220

℃ at rate of 20

℃/min and keep the temperature for 20min,then read the weight loss rate.

3. Oven observation method: Take sample of 3g to place in an aluminum weighing dish with a diameter of 50mm, place one sample every 6L oven, bake it in the oven of 220

℃ for 20min,then open the oven to observe the smoking situation.

In the above experiments, the precision of the balance shall reach 0.1% which means it can be weighed up to one mini-gram, and generally speaking, the analytical balance with the price around 1000 Yuan/set will meet the requirements completely; the temperature control accuracy of oven shall be within 1

℃. The sample of 3-5g shall be moderate, the consistency of the experiment is poor when the sample of 1g is used, and the accuracy of the experiment is relatively poor when the sample of 10g is used.

When wax is placed inthe beaker to observe the smoking properties during the melting process, the heat transfer process will be greatly different due to the influences of particle shape, viscosity and melting point of wax, the smoke can be produced due to local overheating, the consistency of the experiment is poor.

Smoking properties experiment of wax for power coating (first, second, third and fourth grade waxes)

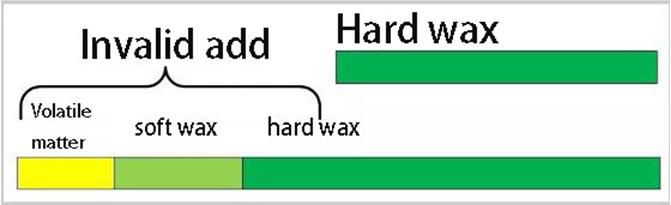

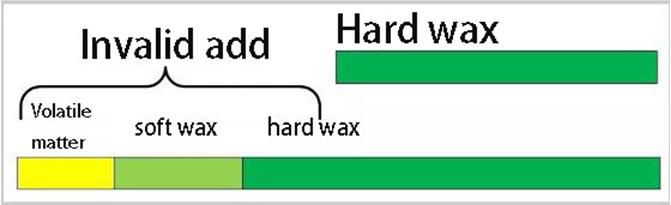

The thermal weight loss of different waxes varies greatly and if the oven weight loss method is used as the criterion, some are less than 1% and some are more than 20%, the wax can be classified to five grades according to thermal weight loss condition:

| |

1stgrade wax |

2ndgrade wax |

3rdgrade wax |

4thgrade wax |

5th grade wax |

| Oven weight loss |

<1% |

1-3% |

3-8% |

8-20% |

>20% |

| Oven observation |

Basically no |

Traces of smoke |

Small amount of smoke |

Moderate amount of smoke |

Plenty of smoke |

In recent years, with the improvement of environmental protection requirements, the waxes in the power coating market mainly are smoking 2

nd/3

rdgrade, but some customers still use 4

thgrade smoking products and the 5

thgrade product is basically unused. The smokes can be obviously observed when the waxes of smoking 3rd, 4

thand 5

thgrade are melted by beaker. The larger odor can generally be smelt when the smoking 5th grade wax is in the solid particle state.

The waxes imported from Europe, America and Japan mainly are 1

stgrade; the main products of Southeast Asia are 3

rdand 4

thgrade with a small amount of 1

stand 2

ndgrade; the domestic products cover from 1

stgrade to 5

thgrade.

The waxes produced and sold by Nanjing Tianshi are first and second grade.

Generally speaking, the wax producing more smokes has plenty of small molecules, this part of the wax will not play a good scratch resistance and wear resistance, but also reduce the scratch resistance of wax with larger molecular weight. So,

reduce the dosage of wax and adding better wax is the right use strategy.

TIANSWAX Successfully Completes Phase II of Nanjing Wax Powder Plant

TIANSWAX Successfully Completes Phase II of Nanjing Wax Powder Plant

Driving the Green Coatings Revolution with High-Performance Wax Innovation: Nanjing Tianshi's Technological Breakthrough and Industry Responsibility P

Driving the Green Coatings Revolution with High-Performance Wax Innovation: Nanjing Tianshi's Technological Breakthrough and Industry Responsibility P

JLU Celebrates 70 Years of Materials Science: Tianshi Group President Delivers Keynote on “Precision Waxing, Changing the World”

JLU Celebrates 70 Years of Materials Science: Tianshi Group President Delivers Keynote on “Precision Waxing, Changing the World”